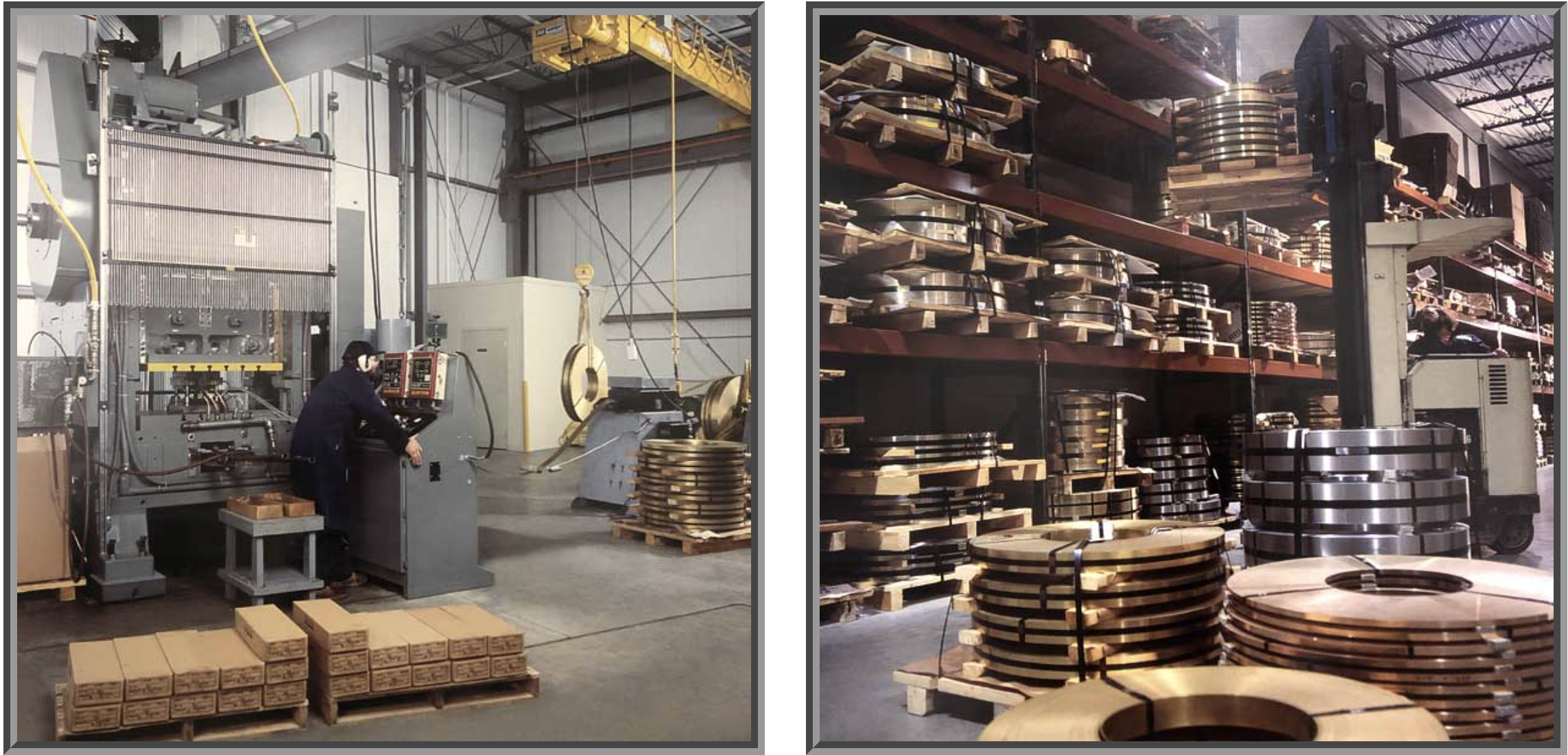

Facilities

We are an ISO 9001:2015 and IATF 16949:2016 registered company located in central Vermont with easy access to major highways and airports. The plant is a spacious and modern 80,000 sq. ft. air-conditioned facility.

Customer Support:

We have developed custom integrated software for:

- Job tracking

- Customer order status inquiries

- Purchasing and inventory control, including off-site stocking programs

- Shipments, Invoicing, packing slips, programmed bar code labeling, Certifications

Barcode Inventory System:

- Raw material

- Metal stampings

- Finishing and secondary work in process

- Finished goods

Design Engineering Equipment:

New England Precision, Inc. has a highly skilled design engineering team equipped with the latest CAD/CAM software, computers and plotters.

Wire EDM Equipment:

- Mitsubishi BA8 wire EDM (self-threading)

- Mitsubishi MV2400R wire EDM (self-threading)

EDM Hole Drill

- Mitsubishi ED2500M

Quality Assurance Equipment:

All measuring instruments are calibrated to conform to ISO 9001:2015 and IATF 16949:2016 requirements. We meet or exceed all customer quality requirements utilizing the latest measuring equipment and inspection equipment. Some of these are:

- Visual SPC shop floor workstations and SPC analysis pack

- Custom, in-house designed gages for fixtures, functional gages and Go / NoGo gages

- Starrett HDV300 Visual Comparator

- (4) Starrett HB400 Optical Comparators with Quadra Chek-200

- United TRU BLUE II Rockwell Hardness Testing System

- Rockwell Tester (3JR-9843)

- Master Mitutoyo gauge block set

- Mitutoyo Drop Indicators

- Mitutoyo Dial Indicators

- Mitutoyo Micrometers: including flat, ball, disk and pin micrometers for special applications

- Milling micrometers

- Mitutoyo Calipers

- Flexbar .006″ to .060″ minus gage pin set

- Flexbar .011” to .250” plus gage pin set

- Flexbar .061″ to .250″ minus gage pin set

- Flexbar .251″ to .500″ minus gage pin set

- Flexbar .251” to .500” plus gage pin set

- Special Go / NoGo pin gages for product specific requirements

- 81 Piece gage block set

- 18″ by 24″ inspection grade granite plate accurate to .0001

- Microscopes, inspection glasses, eye loops, well-lit press room, QA and inspection areas

- Weight and piece counting scales for weights with a precision level down to 0.02 grams, all the way up to Floor Scales for weights as high as 10,000 lbs. Many of our small parts are piece counted using Setra Super II Scales with 4.4 x 0.00005 lb remote scales to obtain better piece count accuracies.

Tool Room Equipment:

Surface Grinders:

- (2) Harig 6 x 18 surface grinder

- (2) Okamoto 6″ x 18″ surface grinder

- Boyar Schultz 612 head 6″ x 18″ surface grinder

- Jones & Shipman S40 6″ x 18″ hydraulic surface grinder

- Okomoto ACC 16-24x

- Jones & Shipman 6″ x 18″ surface grinder

- Millport II 618 6″ x 18″ surface grinder

- Gardner 6 x 18 surface grinder

Milling & Jig Boring Machines:

- (2) TRAK CNC 3-axis milling machine

- (4) Bridgport Series I 2 hp vertical milling machines

- (2) Clausing drill presses

Lathes:

- ]TRAC TRL 16305X

- Turnmaster 15″ X 50″ tool room gap lathe

Miscellaneous toolroom support equipment:

- (1) DoAll ML 16″ vertical band saw

- Lucifer electric heat furnace & tempering oven

- Pacemaker air compressor

- W.F. Wells L-10 auto horizontal cut-off saw

- Disc grinder

- Miller Synchrowave 250 welder (tig & arc)

- Ramco 55 ton industrial hydraulic press

- Pedestal grinder

Stamping Presses:

- Press # 1 Minster 100 ton -Servo roll feed

- Press # 3 Minster 100 ton -Mechanical Roll feed

- Press # 4 Minster 100 ton -Vamco servo feed

- Press # 5 Minster 75 ton -Servo roll feed

- Press # 7 Minster 60 ton OBI -Peterson roll feed

- Press # 8 Bliss 45 ton Roll feed

- Press # 9 Minster 45 ton -Roll feed

- Press #10 Minster 160 ton -Servo feed

- Press #11 Minster 75 ton -Air or Servo feed

- Press #12 Minster 100 ton -Mechanical Roll feed

- Press #13 Perkins 35 ton -Peterson roll feed

- Press #14 Perkins 45 ton -Servo feed

- Press #15 Minster 45 ton -Vamco feed

- Press #18 Minster 60 ton -Servo feed

- Press #19 Minster 32 ton -Air feed

- Press #20 Perkins 45 ton -Peterson roll feed

- Press #21 Minster 75 ton -Servo feed

- Press #22 Minster 32 ton -Servo feed

- Press #23 Minster 45 ton -Servo feed

- Press #24 Perkins 45 ton -Peterson roll feed

- Press #25 Amada 200 ton -Servo feed

- Press #26 Minster 75 ton -Servo feed

- Press #27 Amada 200 ton -Air feed

- Press #40 Minster 100 ton -Servo feed

- Press #41 Minster 100 ton -Servo feed

- Press #42 Minster 100 ton -Servo feed

- Press #43 Minster 45 ton -Air or Servo feed

- Press #61 Bruderer 18 ton -Roll feed

- Press #62 Bruderer 18 ton -Roll feed

- Press #63 Bruderer 18 ton -Roll feed

- Press #71 Minster 45 ton -Vamco feed

- Press #72 Bliss 45 ton Vamco feed

- Press #80 Bliss 45 ton Servo feed

- Press #81 Bruderer 25 ton -Roll feed

- Press #82 Bruderer 25 ton -Roll feed

- Press #83 Bruderer 25 ton -Roll feed

Key Finishing Equipment:

- HME Coinmaster 1

- (4) GIULIANI FC 7-1 Key Milling Machines

- (2) GIULIANI Multimill FDC.8/1 and FC8-1 Milling Machines

Metal Finishing Equipment:

- Ransohoff aqueous wash and heated air dry line

- Blackstone-Ney AS-3000 Ultrasonic wash line

- Industrial Partswash system RB-300

- (2) Almco burnishing system Model # V-10S w/MHS

- Almco barrel tumbler, aqueous wash and heated dry

- (2) Sweco vibratory tumble deburring machine

- (2) New Holland Centrifugal dryers

- Henderson barrel tumbler

- Rampe vibration deburring machine

- Royson cleaning/deburring machine

- (2) Small part vibratory bowl tumblers

Other Services Offered (done by NEP approved outside vendors):

- Plating

- Painting

- Powder coating

- Heat treating

- Tapping

- Misc. secondary operations

New England Precision Inc.

281 Beanville Road

Randolph, Vermont 05060

800-293-4112

© New England Precision Inc.

All rights reserved.

Site development: D2PWebDesign.